My project was a worn, tired dodger where the glass had lots of scratches and scuffs. First I submerged the dodger in a bathtub of water with baby soap and gently agitated to get rid of as much dirt and grit as possible. There was a lot of dirt and grit!

After letting the dodger dry I laid a canvas tarp on my kitchen floor and then covered it with old bath towels to use the kit. I wanted to avoid adding scratches while trying to remove them.

Step 1: Clear Vinyl Cleaner

This step is a lot like using glass cleaner on a window. I let the spray sit for 20 seconds before wiping according to the directions. I was extra careful to get the little bit of glass under the Sunbrella seams so that dirt would not bleed out in later steps and scratch while I was trying to polish. This was a good move because there was a lot of crud under there that stained the Step 1 cloth.

Step 2: Clear Vinyl Stripper

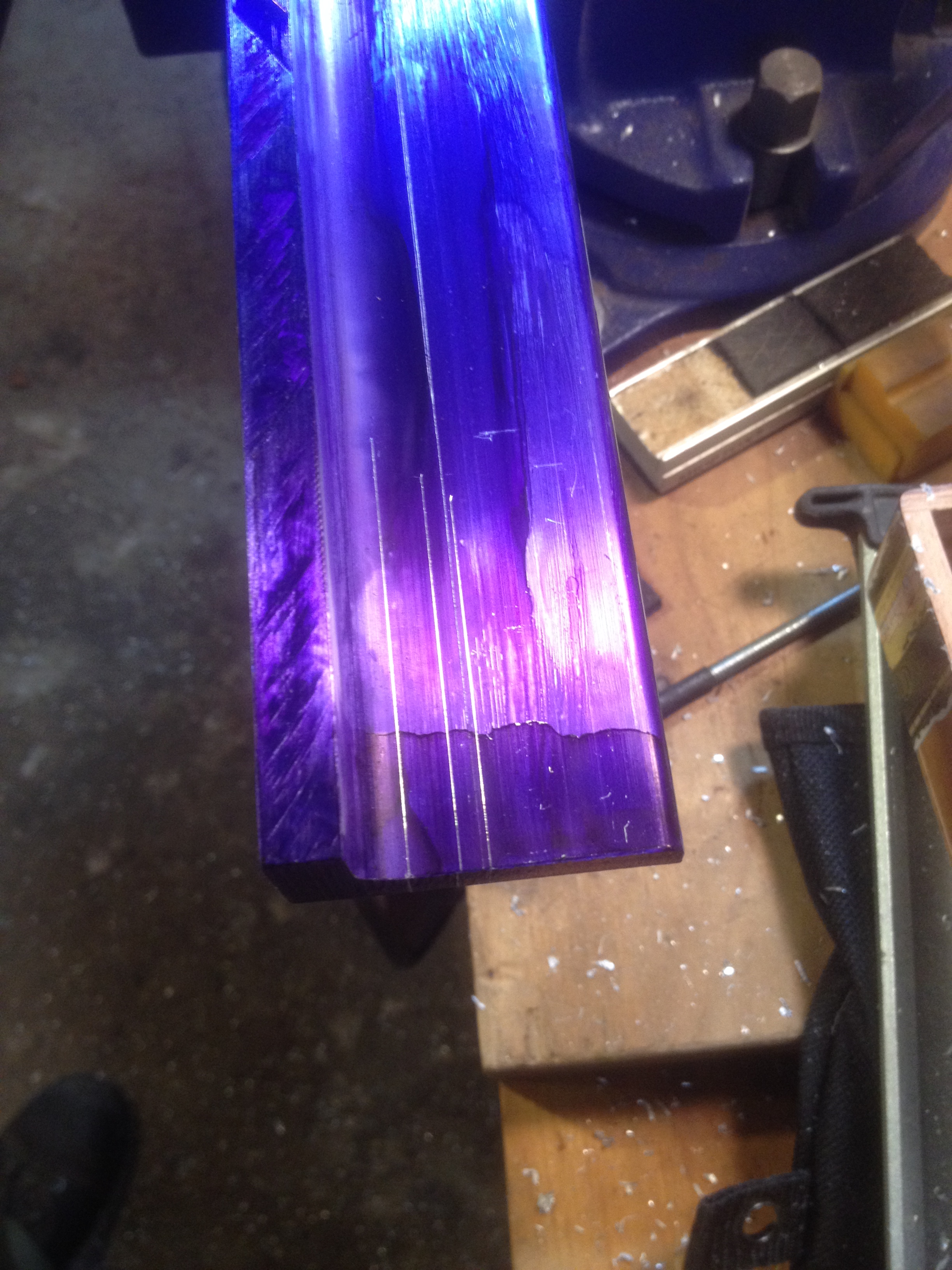

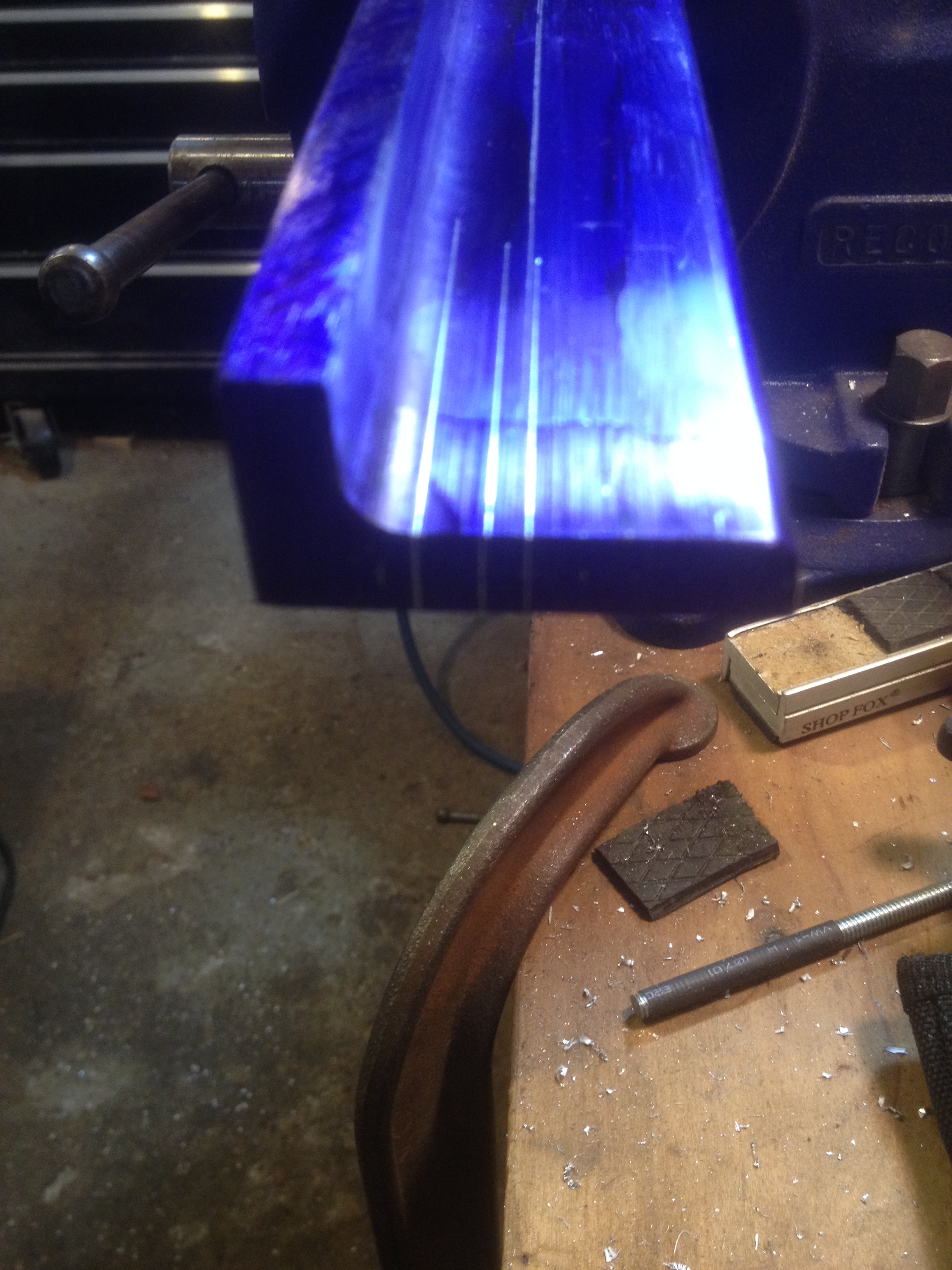

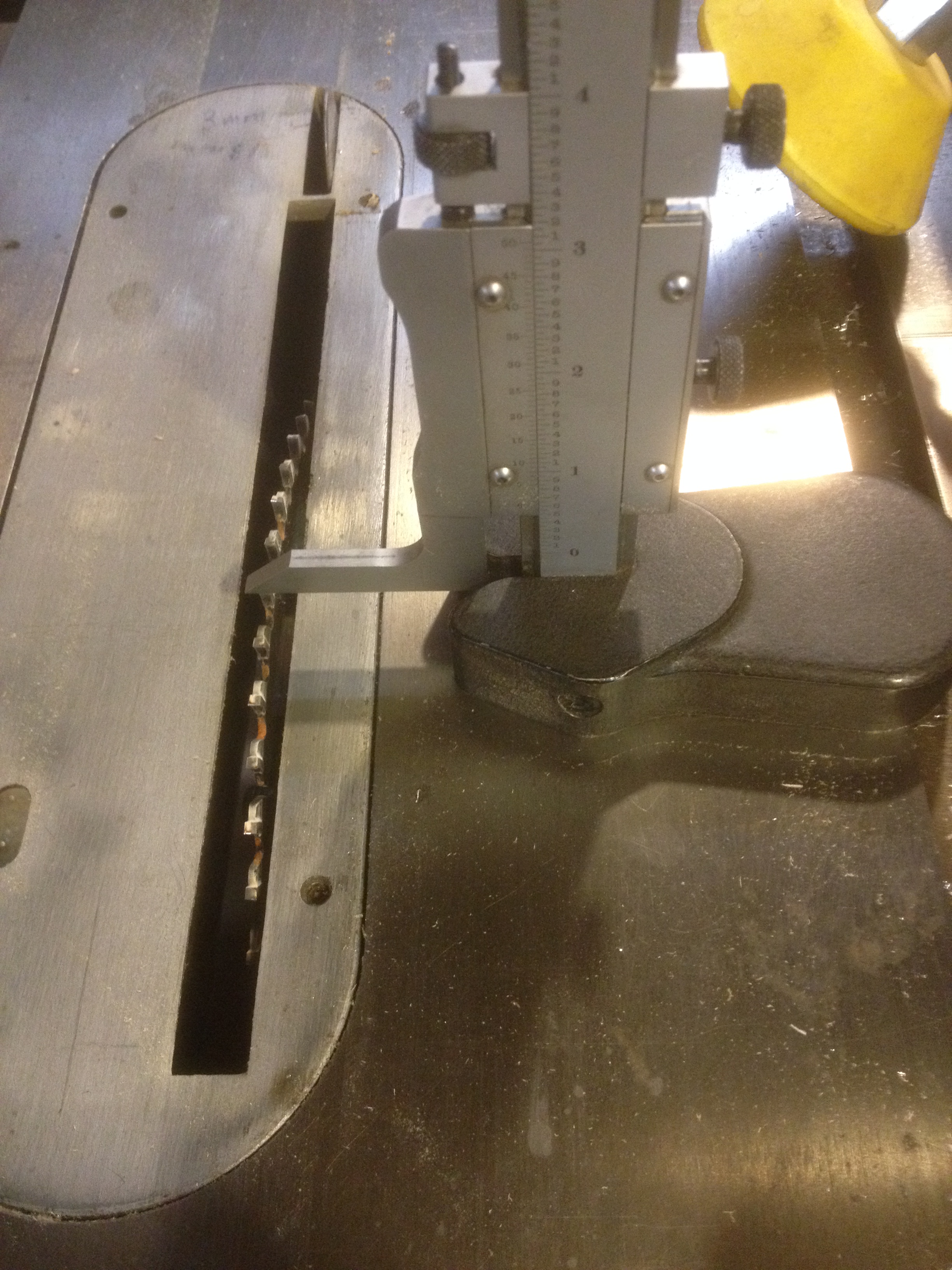

This step is where the magic happens. After doing both sides of the window there was a terrific improvement in clarity. The glass was also much smoother so I expect it will shed water much more readily now. For each panel of glass I repeated Step 2 twice to be sure I didn't miss anything. Scratches, scuffs and hazing all disappeared. Remaining were a few deep scratches and scuffs. The directions recommend performing Step 3 on each panel after Step 2 but I did Step 3 all at once on each side of the dodger without any problems.

Step 2 isn't easy, I worked up a sweat polishing each panel and I had to switch arms. But the effort was worth it!

Step 3: Clear Vinyl Protectant

This step is easy, wipe on, let it dry, get it wet again and buff until dry. Enjoy your newly clear windows!

Conclusion

Even after my excessive repetition of Step 2 there was still plenty of product left to repeat the entire process and plenty of product to reapply the cleaner and protectant for later maintenance. I recommend marking the cloths and sponges with a sharpie so that you don't contaminate the Step 2 cloth with Step 1 grit.

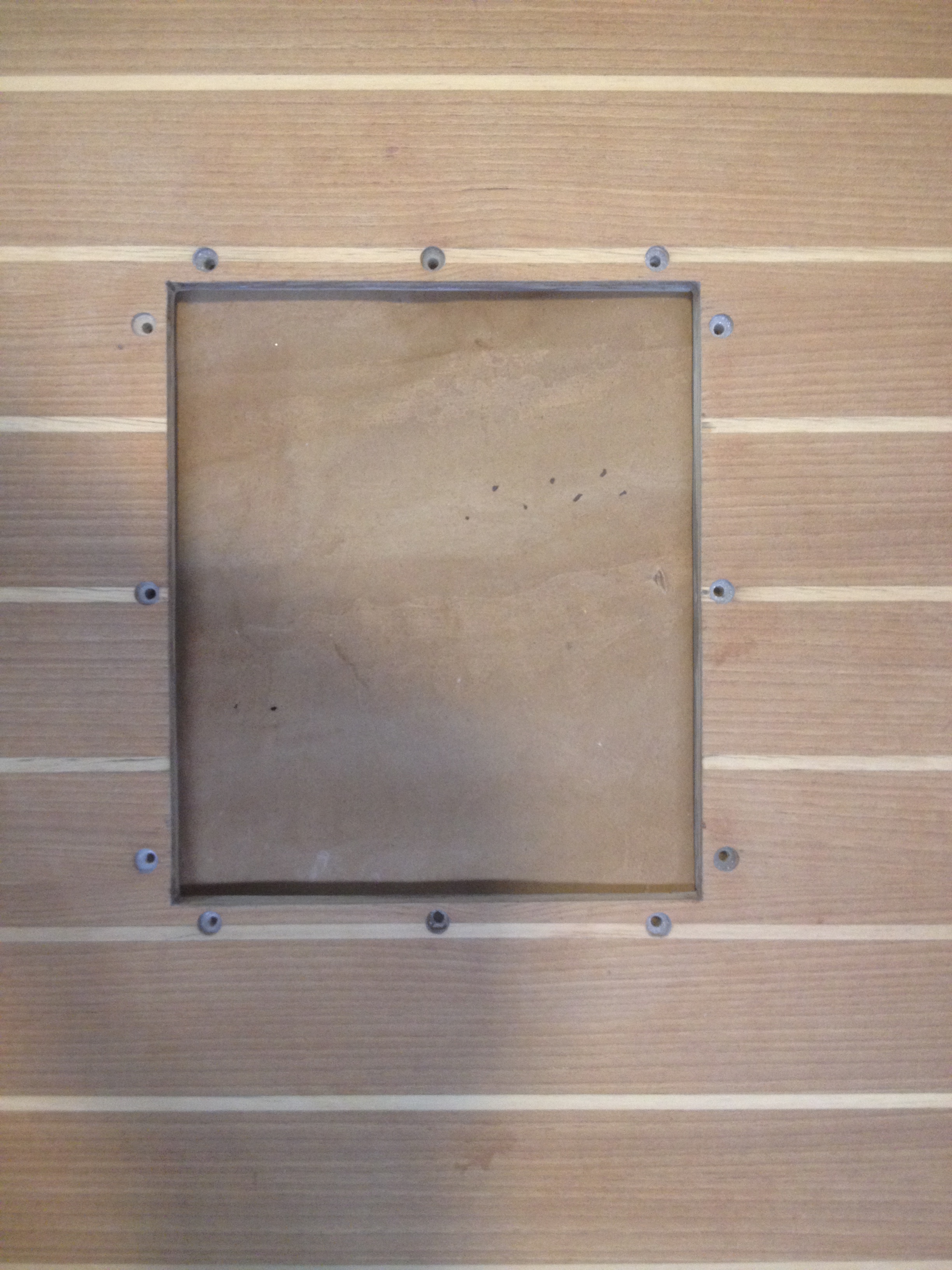

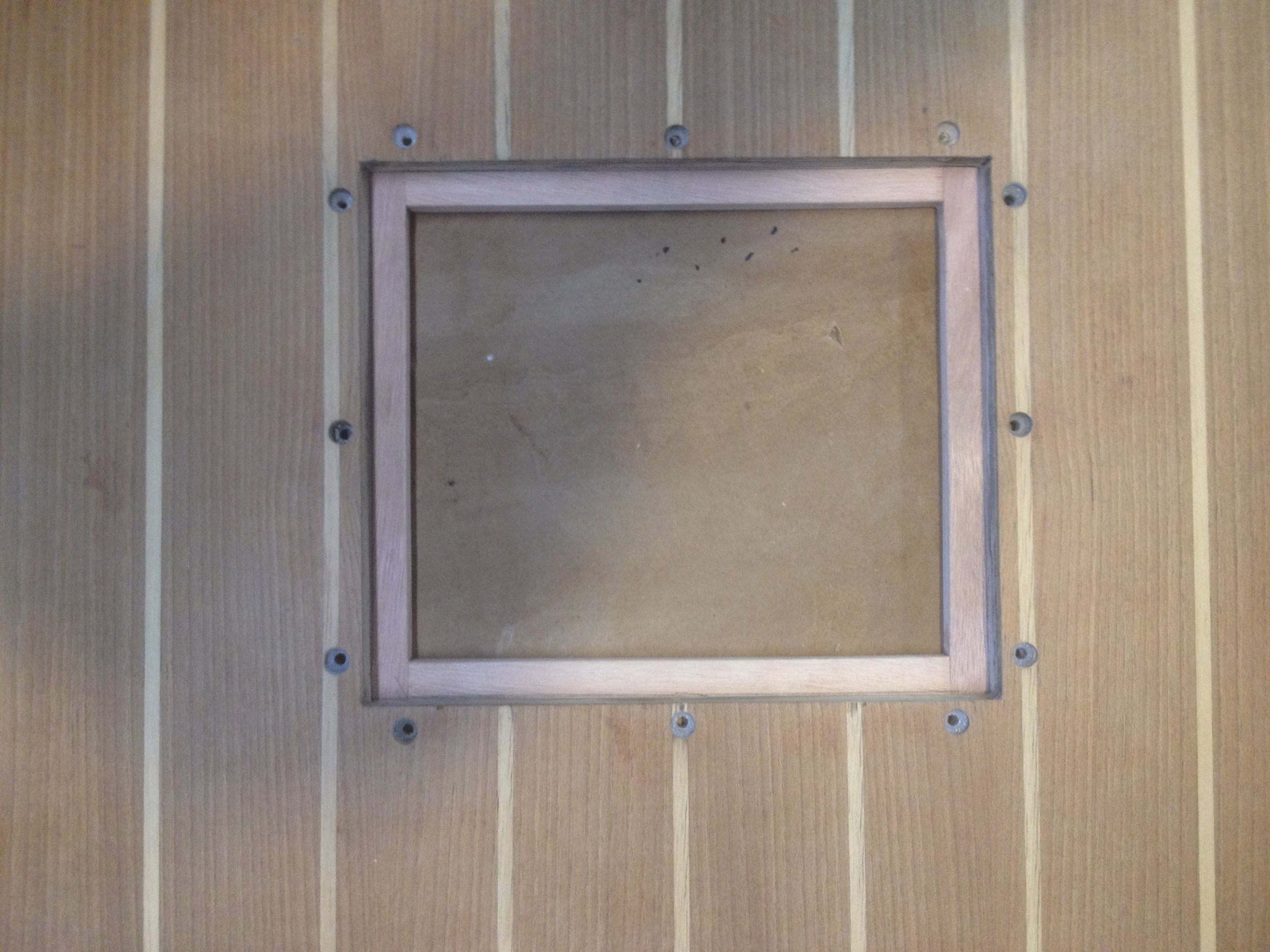

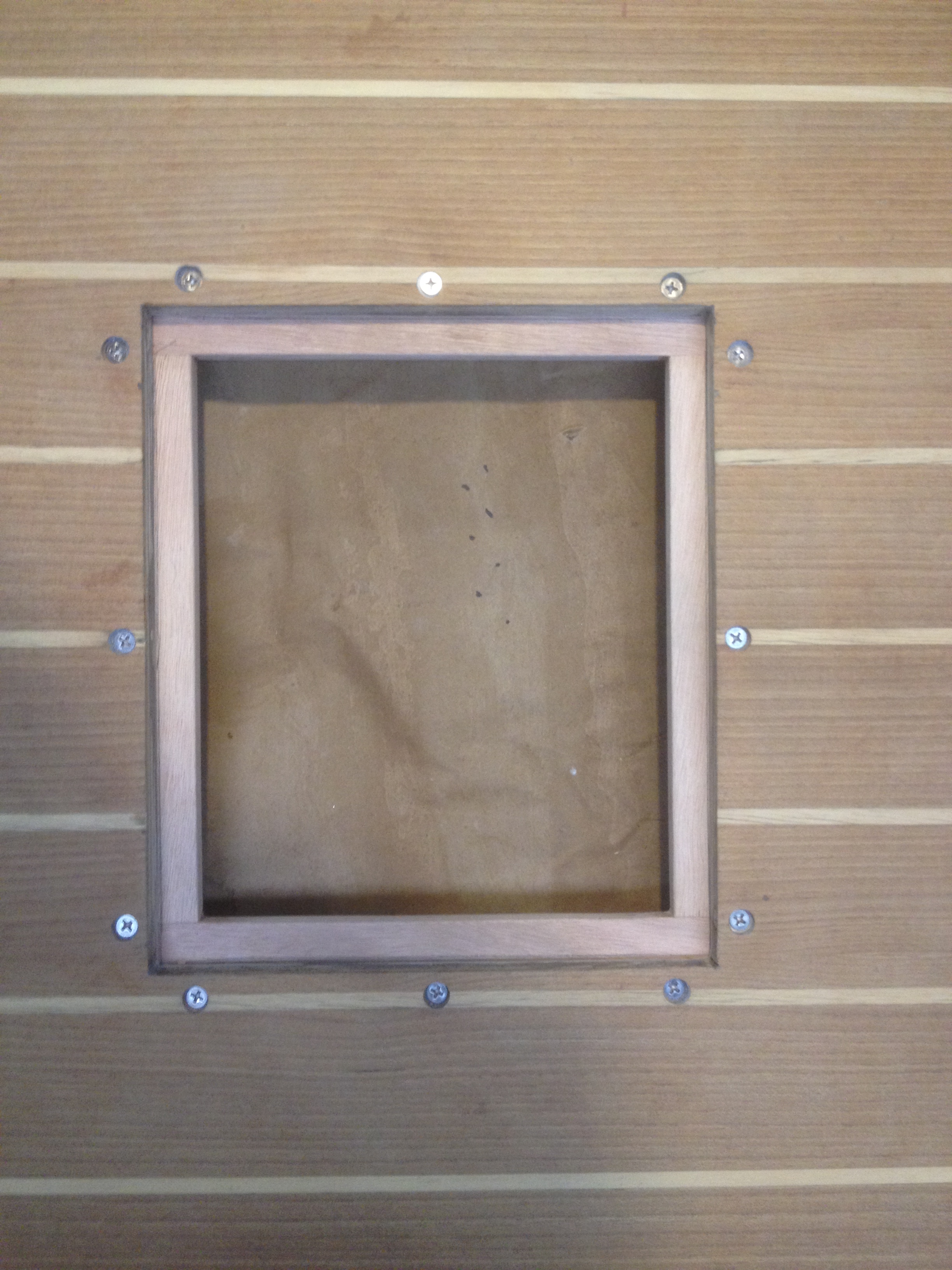

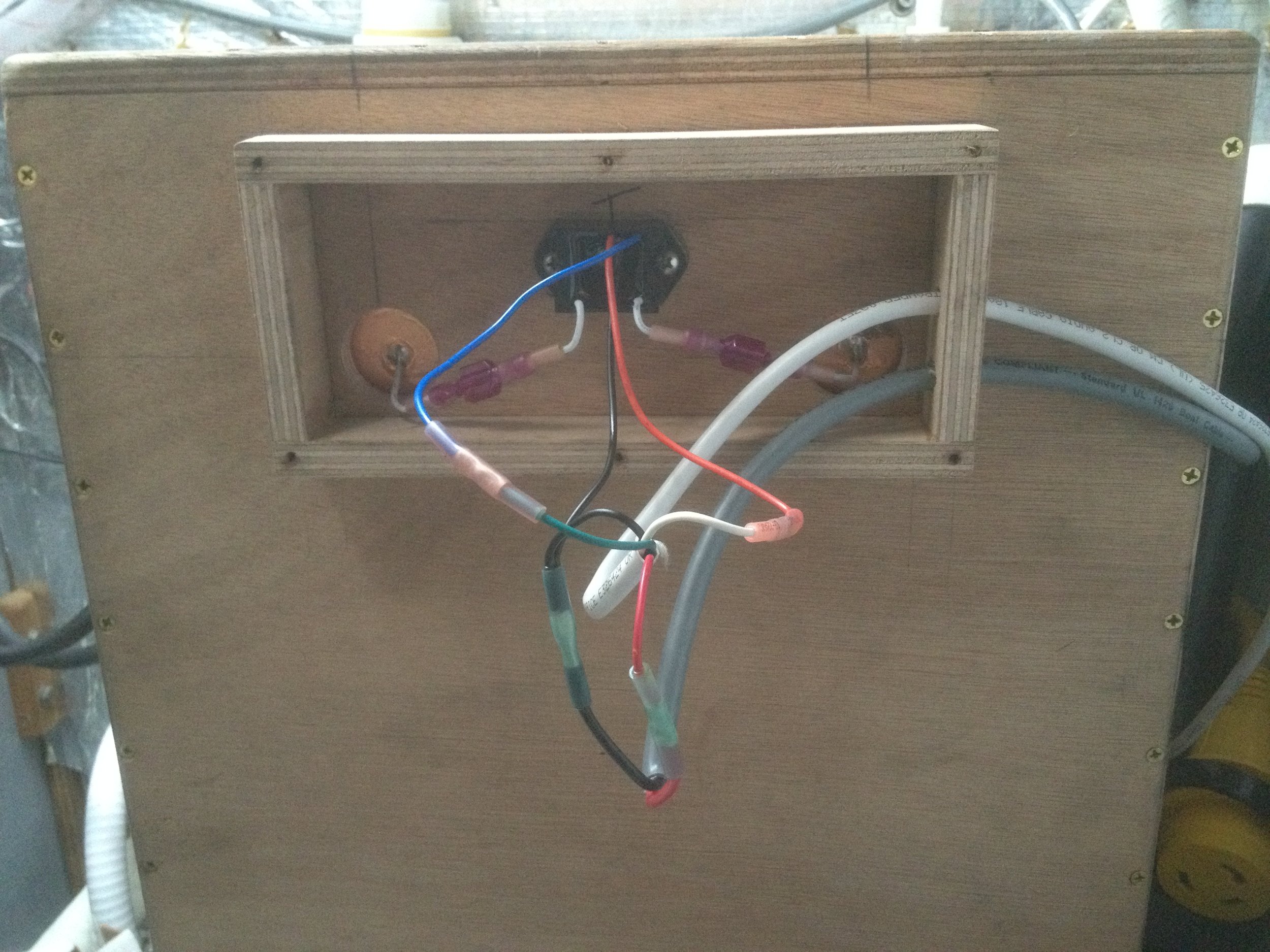

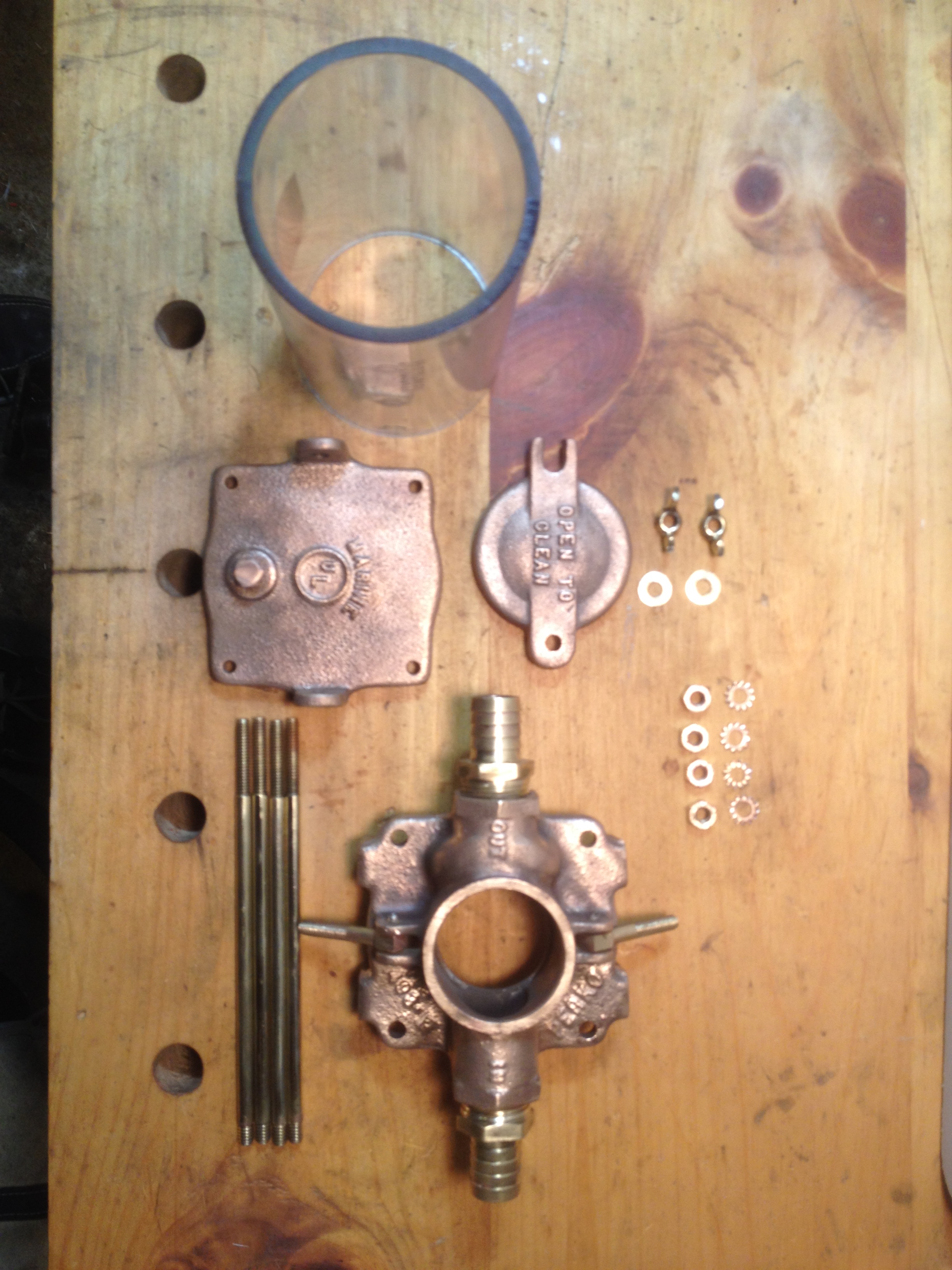

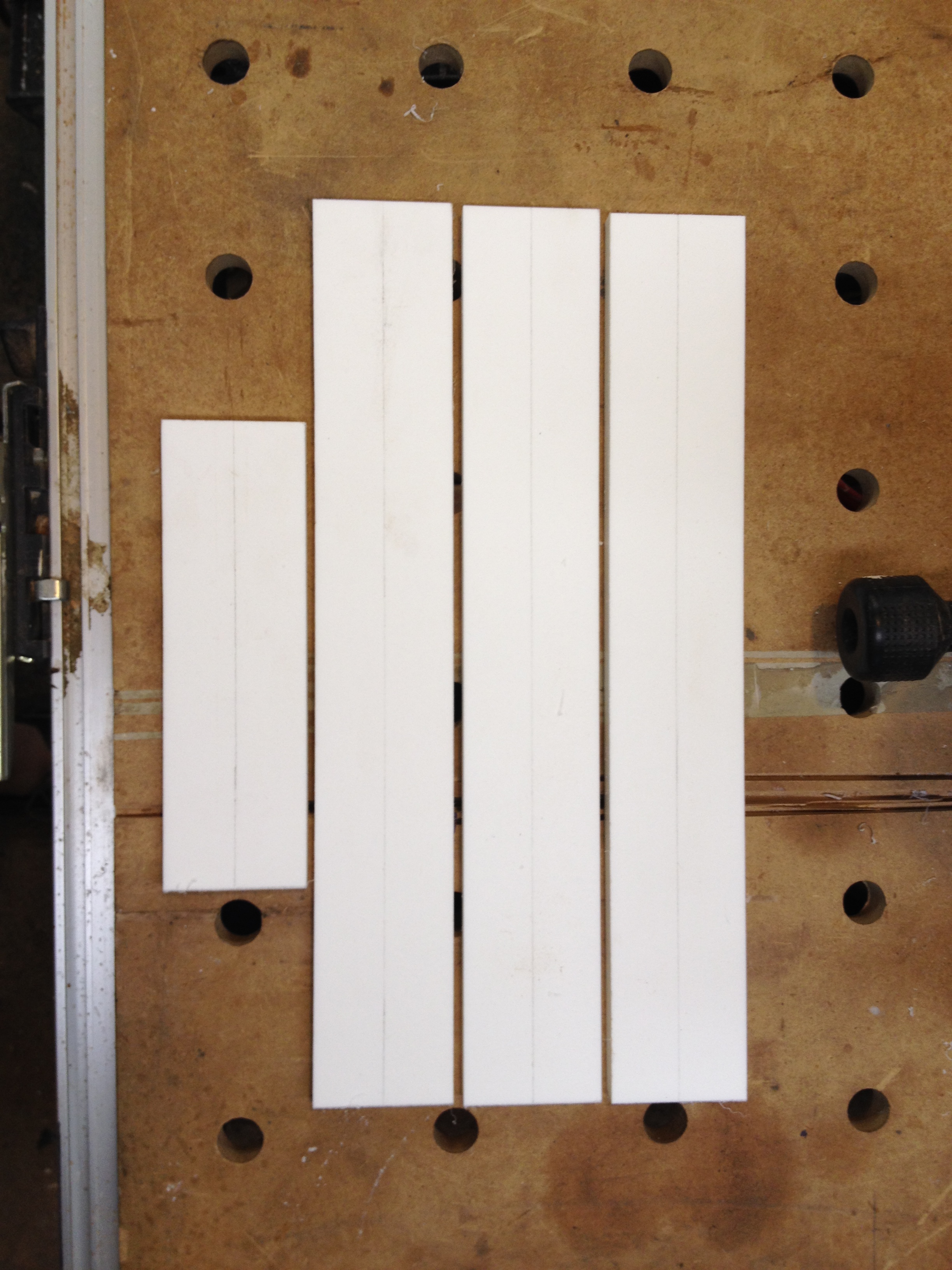

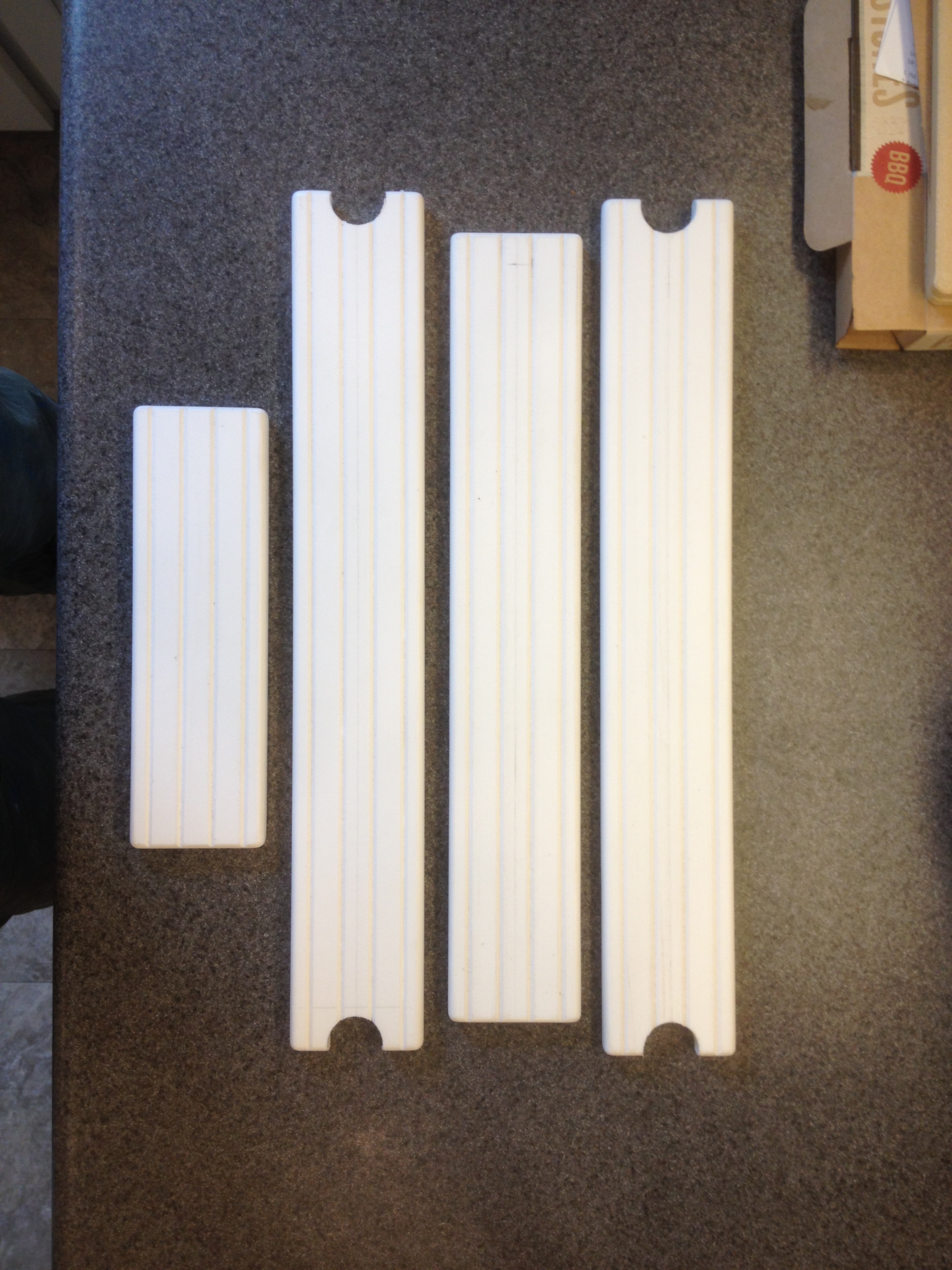

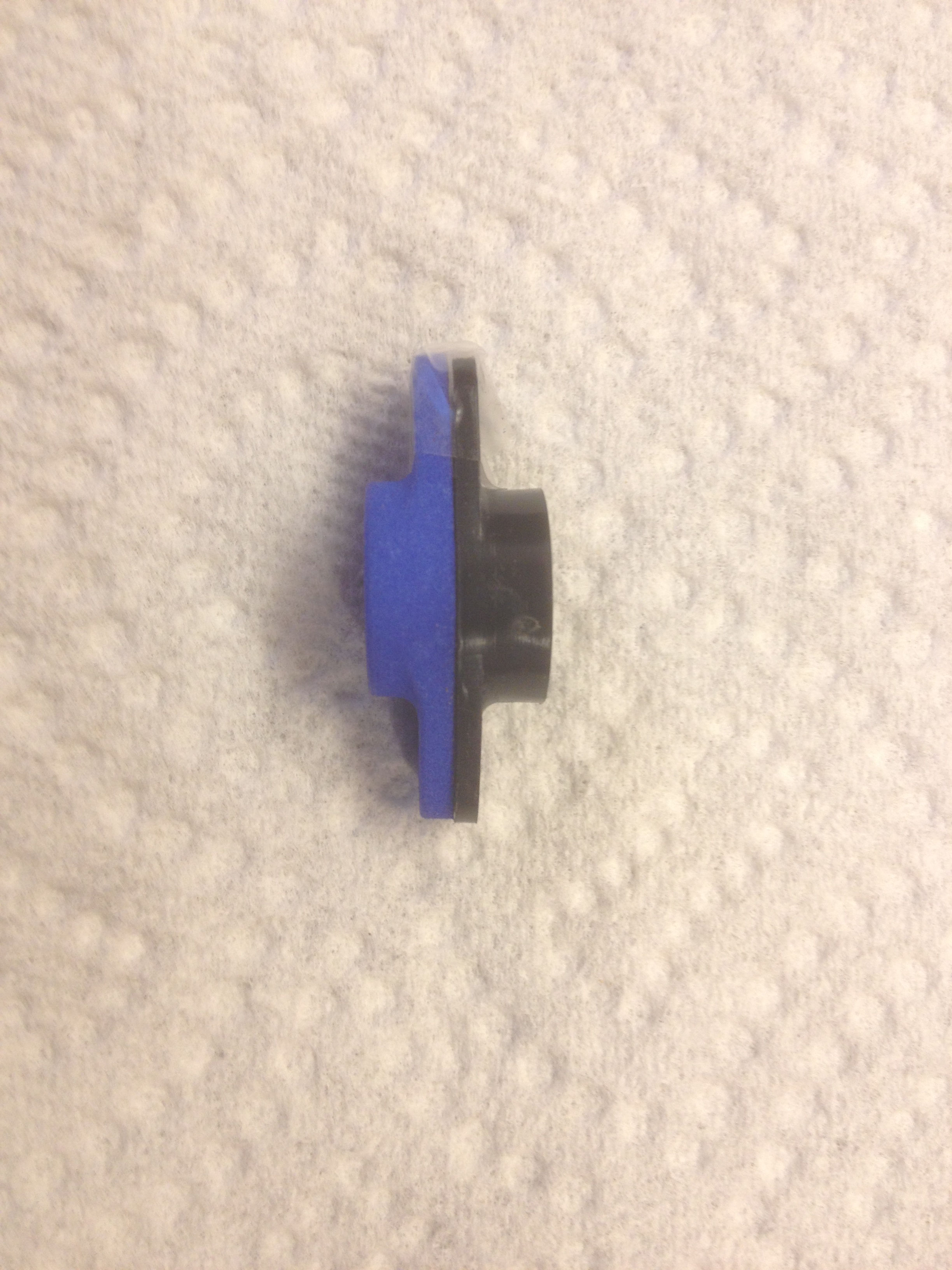

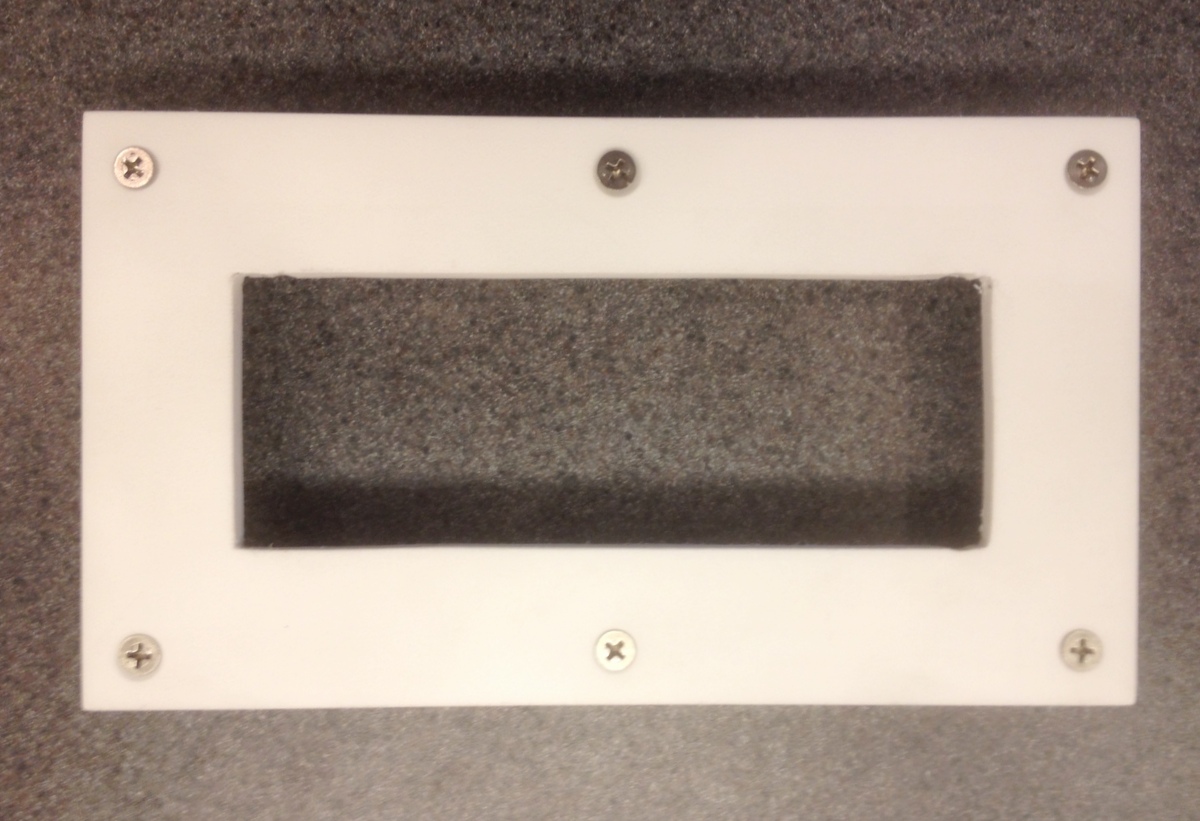

A gallery with a sample of my results is below. The clarity up against the towel masks just how good the results were but the view through the plastic into the distance gives you a good idea of just how much improvement I saw. Below the gallery is a picture from Eisen Shine showing what comes in a kit along with a link to purchase at Amazon.com.

For folks thinking of selling their boat I think a little sweat equity to get better looking glass would be a great move. How many awesome boat products are only $60?